Reduction of plastic waste: A tangible action!

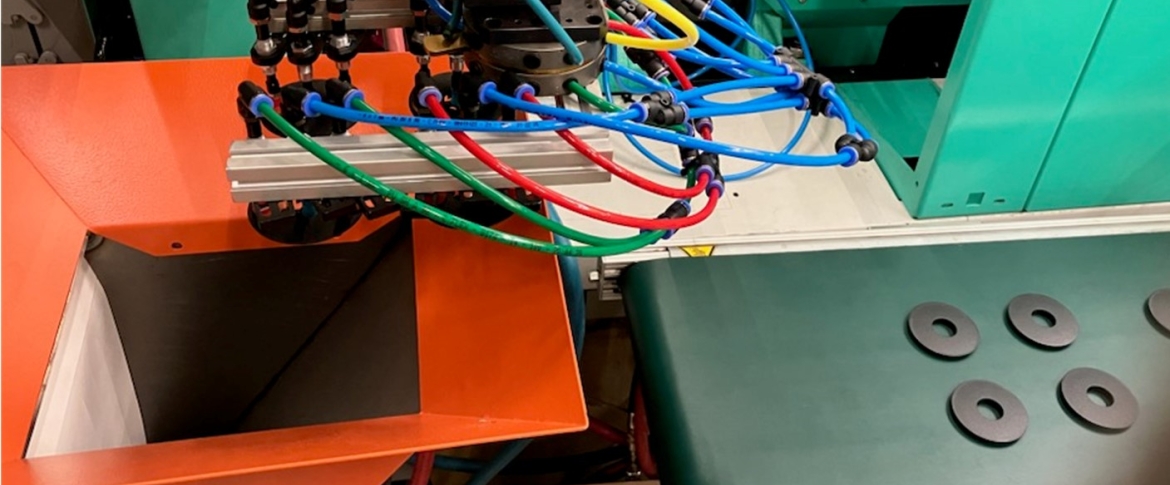

As part of our LEAN initiatives, we have intensified our focus on waste and non-value-adding processes. Consequently, a grinder has been installed directly next to the injection molding machines for recycling sprue material. The sprue material is ground and directly suctioned back up to the injection molding machines. This process provides us with the following benefits:

- Direct recycling of clean industrial surplus plastic

- More floor space in the production area

- Reduced time spent handling pallets filled with sprue material for the grinder

- Reduced time spent on grinding

- Elimination of drying process before recycling

- No storage required for the next production run

- No consumption of plastic bags for the next production run

- Reduced forklift movement

This automation is most feasible for materials without glass fillers to prevent dust and environmental concerns in production. The implementation is done wherever possible in alignment with the customer's desire and requirement to use recycled plastic in their components.

Dansk

Dansk Engelsk

Engelsk