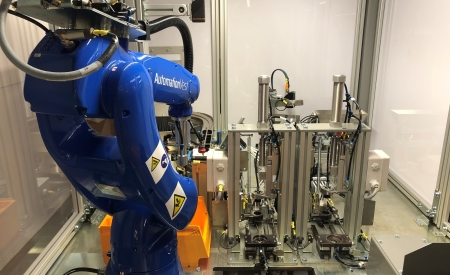

At Unika, we are currently cooperating with a customer on an automation project, where we install a robot cell for:

- Automatic quality control of the injection molded parts

- Mounting of connecting pins for PCBs

- Further quality inspection with automatic vision systems

- Robot packing of these high-tech plastic components.

The optimal process choice for mass production in this case is full automation, as it ensures a constant quality during the added value of the components after the injection molding process. This approach minimizes unilateral repetitive manual work for the process operators. That combined with a 100% item inspection, where any process variation exceeding tolerance and any defective items are detected and removed from the process flow, makes it optimal.

A test team from Unika, consisting of a tool setter, a tool setter apprentice, and a quality employee, visited the manufacturer of the robot cell in week 26 2024, to execute the Factory Acceptance Test of the equipment. During the test, some possible improvement were identified which had to be implemented before the robot cell could be delivered to Unika.

We have just received the automation cell and are looking forward to start it.

Dansk

Dansk Engelsk

Engelsk