Product development

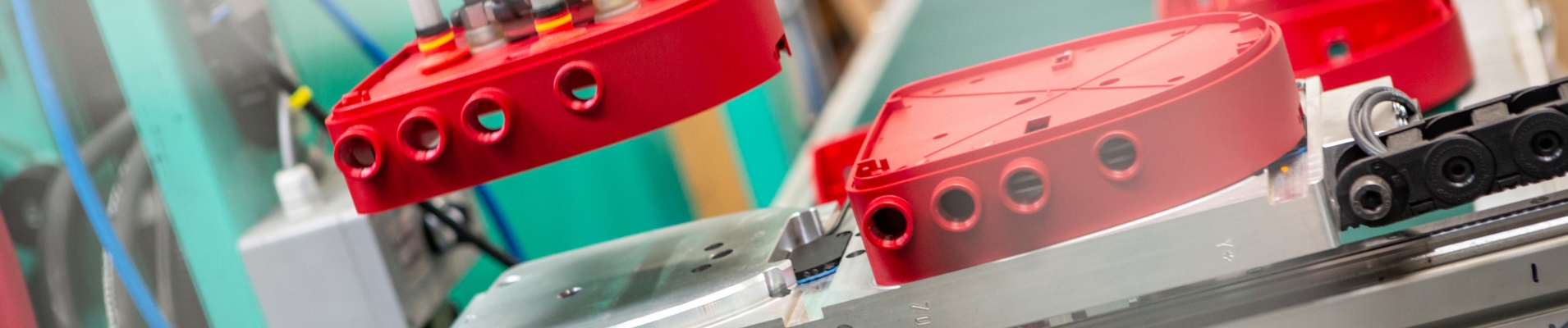

We act as a sparring partner for our customers and possess excellent know-how within the production of injection mould plastics. Because of experience for over 40 years now, we have created an understanding of the problems, our customers present and based on a unique business model, in which we have joined the tools and plastics departments, we offer a highly qualified development process in an extremely short span of time.

From idea to product

Our development team consist of well-experienced plast technicians among tools- and 3D-specialists, who work together with the customer’s project manager, various production specialists and the people responsible for the customer’s sales. In unison, they map out all mechanical and physical demands as well as dictate the requirements for the finished product. We work either from structural plans or merely from the customer’s own idea.

Based on the above, we design the component in 3D and simulate the injection mould process. This displays possible weaknesses in the production of the component and forms the basis for future decisions. Parts of the team meet again, and the meetings continue until all aspects are clarified. Unika is now ready to initiate the development of the tool for component production, and once this is approved, the plastics production is started.

It is a significant advantage for our customers that we offer up in-house specialists in tools and plastics. This is one of the key reasons why we have been chosen to solve specialist assignments at large Danish companies.

Dansk

Dansk Engelsk

Engelsk