Highly equipped tool department

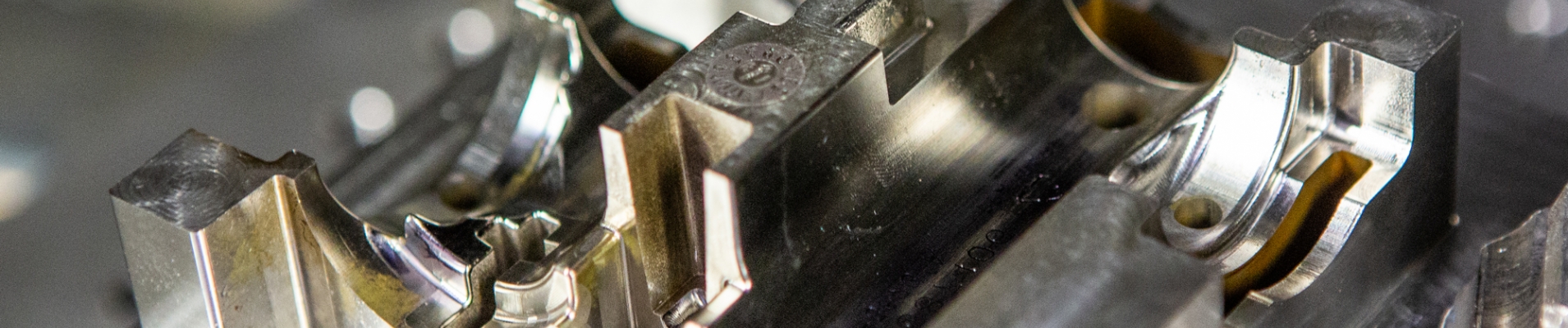

Unika offers its own tool making with the latest technology in tool making. We manufacture, develop, restore, construct tools equipment for injection mould plastics in one of Denmark's most well-equipped tooling departments.

With our know-how and the many years of experience with manufacturing, development and restoring tools, we help our customers with projects within plastic molds, press and punching tools, measuring tools, etc.

Technology development is closely monitored at Unika and we continuously update with new, energy-efficient machines for the production of functional tools and molds for in house plastic injection molding.

As a central part of the solution of any task, we offer a close customer collaboration, where professional advice, communication and sparring are paramount.

Our tool department consists of highly specialized employees with many years of experience and we have the capacity to ensure an optimum result ind the shortest span of time possible.

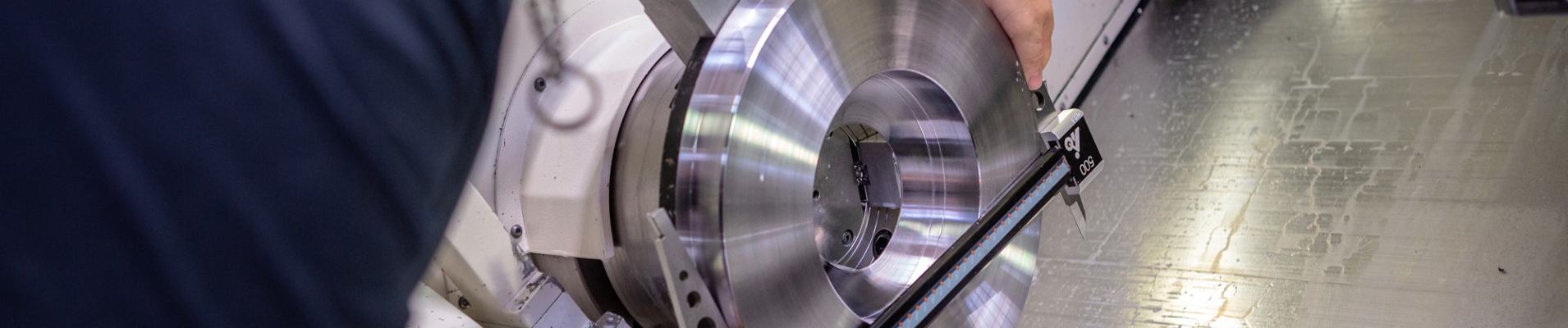

Accuracy

The tools are re-examined on our Zeiss measuring machine and a measurement report is produced. This is our customer’s guarantee that all measurements specified for control match the requirements.

We also measure tools where we receive a scan of the tool rather than have the tool in hand. Typically, this occurs if the tool consists of many small details, where angles and measurements have to be mapped out in 3D.

If there is no drawing for a subject, our newest Zeiss measuring machine can perform reverse engineering, which means that, based on the machine's measurement data, we can make drawings and 3D models of the subject.

Dansk

Dansk Engelsk

Engelsk